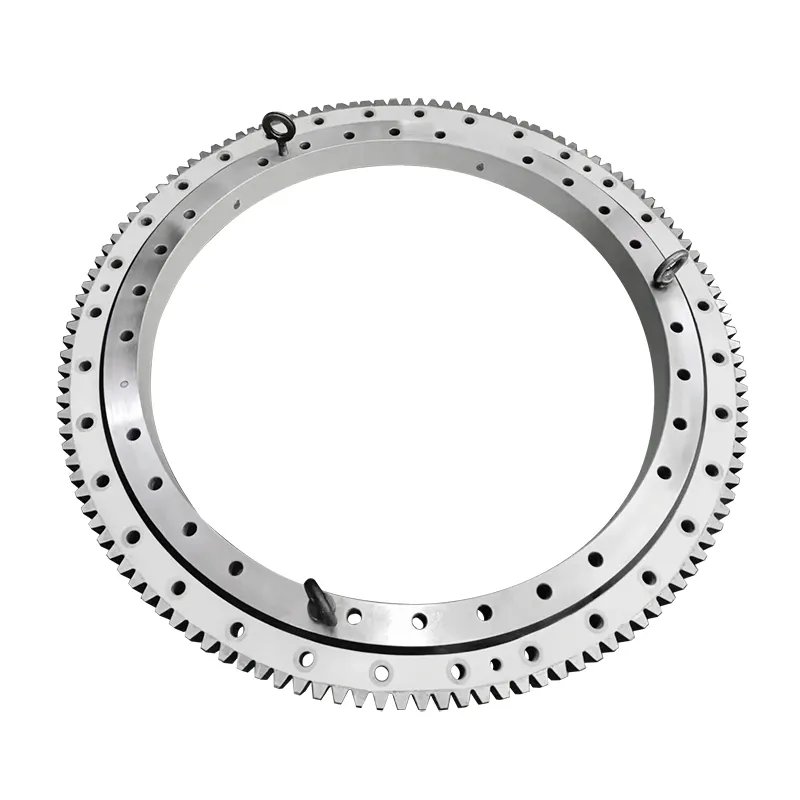

Four-point contact ball bearings are radial single row angular contact ball bearings designed to support axial loads in both directions. They can support a certain degree of radial loads and take up significantly less axial space than double row bearings. The inner ring is a split inner ring, which allows a higher number of balls to be loaded and increases the load carrying capacity. Selecting a four-point contact ball bearing involves considering several key factors to ensure it suits the specific application.

Axial Load: Four-point contact ball bearings can handle both radial and axial loads. Ensure that the bearing’s axial load capacity meets the application’s requirements.

Radial Load: Determine the radial load the bearing will be subjected to. Four-point contact ball bearings typically have a lower radial load capacity compared to other ball bearings, so this needs to be considered.

Combined Loads: Four-point contact bearings are particularly useful in applications where both radial and axial loads are present. Make sure to calculate and consider the resulting combined load.

Bearing Diameter: The size of the bearing should match the shaft diameter or housing in which it will be installed.

Contact Angle: Four-point contact bearings have a contact angle of about 35° that allows them to support both axial and radial loads. Check if this angle aligns with your application’s needs.

Clearance or Preload: This defines the amount of internal clearance between the rolling elements and raceways, which influences the bearing’s performance under load.

Rotational Speed: Four-point contact bearings are generally suitable for moderate to high-speed operations, but you should verify the maximum speed the bearing can handle by checking the manufacturer's catalog.

Lubrication: High-speed applications may require special lubrication (oil or grease). Make sure to select a bearing that is compatible with the lubrication type you plan to use.

Temperature: Consider the operating temperature range. Some four-point contact ball bearings are available with seals or shields for dust, moisture, and temperature resistance.

Corrosion Resistance: If the bearing will be exposed to corrosive environments (e.g., chemicals or water), choose a bearing with appropriate material coatings, such as stainless steel or ceramic bearings.

Precision Class: Bearings come in different accuracy classes (e.g., P0, P6, P5). For high-precision machinery, select a bearing with a higher accuracy grade.

Radial Runout and Axial Runout: For high-precision applications, the bearing’s radial and axial runout tolerances should be evaluated.

...

For more detailed information on four-point contact ball bearing selection, please click here: https://www.mcslewingbearings.com/en/a/news/four-point-contact-ball-bearing-selection.html