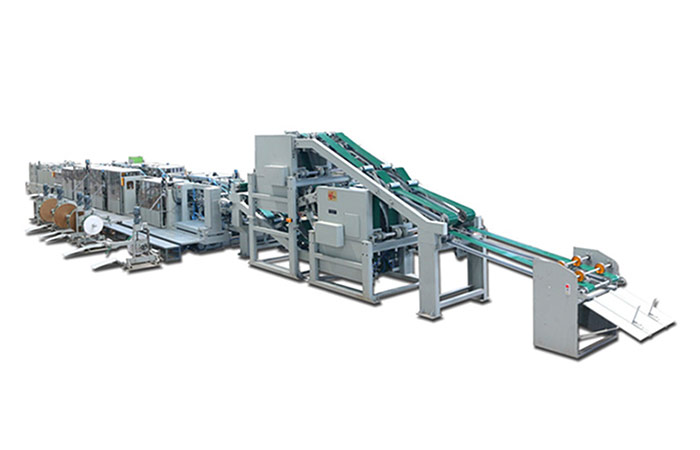

A “square bottom machine” typically refers to a piece of equipment or machinery designed for the production of square-bottomed bags or packaging. Square-bottom bags are commonly used in various industries for packaging purposes, such as in grocery stores, retail shops, and food service establishments. These bags have a flat, square bottom that allows them to stand upright and hold items more securely than traditional flat-bottom bags.

Bag or Container Formation: The primary function of a square bottom machine is to form bags or containers with a square or rectangular bottom shape. This can be accomplished by folding and sealing the material in a way that creates a flat, stable bottom.

Material Feeding: Square bottom machines often have mechanisms for feeding and guiding the material (usually paper or plastic) through the machine. This ensures that the material is properly positioned for bag formation.

Bottom Folding and Sealing: The machine typically folds and seals the bottom of the bag or container. This process is critical for creating the square bottom shape and ensuring that the bag is sturdy and can stand upright.

Side Sealing: In addition to the bottom, square bottom machines may also perform side sealing to create the main body of the bag or container. This involves sealing the sides of the material to form a tube or rectangular shape.

Cutting and Trimming: Some square bottom machines may include cutting and trimming mechanisms to trim excess material and create a neat, uniform appearance for the bags or containers.

Printing and Labeling (Optional): Depending on the specific machine and application, it may have the capability to print labels, logos, or other information directly onto the bags or containers as they are being formed.

...

For more detailed information about the function of the square bottom machine, please click to visit: https://www.lyhuatianm.com/products-information/square-bottom-machine-functions.html